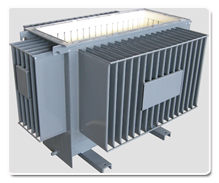

TANK CONSTRUCTION

TANK INTEGRITY IS ESSENTIAL FOR RELIABILITY AND LONG TRANSFORMER LIFE. TO ENSURE A PERFECT FIT TO THE APPLICATION,SEC DESIGNS AND FABRICATES ALL TRANSFORMER TANKS TO CUSTOMER SPECIFICATIONS.

- TANKS FABRICATED FROM HOT-ROLLED, LOW CARBON STEEL PLATES ARE PLASMA CUT TO CRITICAL TOLERANCES THEN JOINED VIA SUBMERGED ARC WELDING TO ENSURE AGAINST CRACKED SEAMS AND IRREGULARITIES.

- TANKS ARE BRACED TO WITHSTAND VACUUM AND PRESSURES 25% GREATER THAN ACHIEVED DURING NORMAL OPERATION.

- TANK CORNERS ARE BENT TO ELIMINATE CORNER WELDS.

- JACK PADS AND LIFTING HOOKS ARE PROVIDED ON THE TANK FOR LIFTING, JACKING OR PULLING.

- COMPLETED CORE AND COIL ASSEMBLY IS FITTED TO GUIDES IN THE TANK AND IS SOLIDLY BRACED TO PREVENT SHIFTING DURING SHIPMENT.

- TRANSFORMER TANK COVERS ARE SLIGHTLY DOMED TO PREVENT WATER ACCUMULATION.

- OPENINGS IN THE COVER USE RAISED FLANGES WITH MACHINED GASKET GROOVES TO PREVENT BOLTS FROM EXTENDING THROUGH THE COVER.

DURING MANUFACTURING, THE TANK AND COVER UNDERGO AN "OVER-PRESSURE TEST" TO VERIFY THE TANK AND COVER ASSEMBLY IS LEAK-FREE.

SAHABHANT ELECTRIC CO.,LTD.

SAHABHANT ELECTRIC CO.,LTD.